Understanding Trenchless Sewer Repair: Benefits and Techniques

Outline and Why Trenchless Sewer Repair Matters

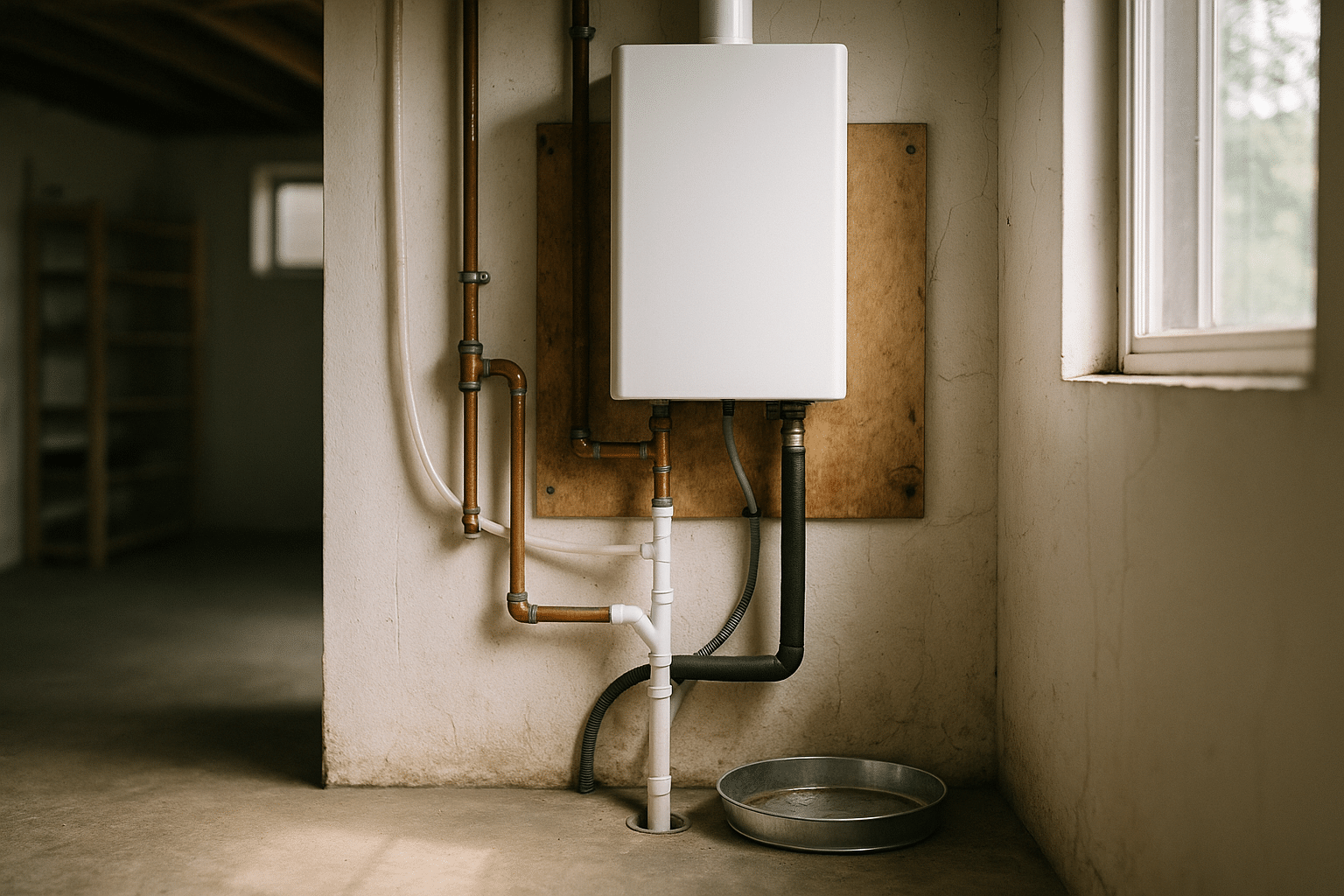

Trenchless sewer repair describes a family of methods that rehabilitate or replace underground pipes with minimal surface excavation. Instead of long, open trenches, crews use small access points to repair lines from the inside or to pull new pipe along the path of the old one. For homeowners and facility managers, the appeal is straightforward: fewer disruptions, faster timelines, and reduced restoration after the work is complete. Yet the approach is more than convenience; it reflects decades of engineering aimed at extending infrastructure life in dense neighborhoods and sensitive landscapes.

Outline of this article:

– Key concepts and vocabulary behind trenchless methods.

– A comparison of leading techniques: lining, bursting, spot repairs, and sliplining.

– How to diagnose a failing sewer and choose an approach.

– A deep dive into pipe relining materials, curing, and performance.

– Cost ranges, permitting, environmental impacts, and a practical conclusion.

Trenchless methods emerged to solve recurring issues: root intrusion through joints, corrosion in metal pipes, cracking in vitrified clay, and groundwater infiltration that overwhelms systems during storms. Traditional dig-and-replace fixes these problems but often converts a pipe issue into a landscaping or hardscape project. In contrast, a trenchless crew may work within a single day, using video inspection to confirm defects, cleaning to clear deposits, and then restoring the pipe with minimal surface disturbance. Municipal experience suggests that established techniques, when designed and installed to recognized standards, can provide decades of service life, making them a credible alternative to full excavation. Homeowners benefit from less downtime, fewer surprises, and a cleaner worksite, while communities gain from reduced traffic interruption and lower construction waste. The rest of this guide breaks down how each method works, where it excels, and what trade-offs to understand before you sign a contract.

Trenchless Methods and How They Compare

Trenchless technologies fall into two broad categories: rehabilitation and replacement. Rehabilitation restores the function of an existing pipe, while replacement installs a new pipe along the old alignment with limited digging. Understanding the mechanics of each method helps set realistic expectations about lifespan, flow capacity, and disruption.

Cured-in-place pipe (CIPP) lining is among the most widely used rehabilitation techniques. A resin-saturated liner is inverted or pulled into the host pipe through an access point, then cured with hot water, steam, or ultraviolet light to form a new, jointless pipe within the old one. The result spans cracks, seals leaks, and resists root intrusion. When designed under established standards, liner thickness and stiffness are matched to ground loads and host pipe condition. Advantages include rapid installation and a smooth interior that can maintain or modestly improve hydraulic performance despite a slight diameter reduction. Considerations include careful cleaning, reinstating lateral connections, and odor control during curing.

Pipe bursting is a replacement method. A bursting head is pulled through the existing pipe, fracturing it outward while towing in a new pipe of equal or larger diameter. Because it requires entry and exit pits, it involves more surface disturbance than lining, yet far less than open trench. It shines where the host pipe is heavily collapsed, severely offset, or undersized. Soil type and proximity to other utilities influence feasibility, as bursting exerts outward forces. In areas with dense utility corridors, additional planning reduces risk.

Sliplining places a slightly smaller carrier pipe inside the old one, grouted in place. It is mechanically simple and durable but reduces internal diameter more than thin-walled liners, which can impact capacity. Point repairs, sometimes called sectional liners, target localized defects such as isolated cracks or offset joints without lining the entire run. Spray-in-place linings can also be used for specific scenarios, though design verification and surface preparation are critical to performance.

Method selection is context-driven:

– CIPP lining: efficient for continuous cracks, infiltration, and root intrusion with a largely intact host.

– Pipe bursting: effective when structural failure or significant deformation prevents lining or when upsizing is needed.

– Sliplining: useful in straight runs where diameter loss is acceptable and simplicity is desired.

– Point repairs: cost-effective for limited defects discovered on CCTV.

In short, lining rehabilitates, bursting replaces, and both aim to achieve structural integrity with far less disruption than open trench replacement. The right choice balances structural needs, hydraulic goals, site constraints, and budget.

From Diagnosis to Decision: Assessing a Sewer Problem

Successful trenchless projects begin with sound diagnostics. A closed-circuit television (CCTV) inspection documents pipe material, diameter, slope, and defects. Technicians typically clean the line with jetting or mechanical cutters before the camera survey to reveal the true condition. The resulting footage allows classification of issues: longitudinal cracks, circumferential fractures, root intrusion, offsets at joints, sags, corrosion, or obstructions. Accurate mapping of lateral connections is essential, since these must be reopened after lining and protected during bursting.

Site conditions are equally important. Soil type, groundwater level, and surface features influence both risks and logistics. For example, high groundwater may drive infiltration through joints and complicate curing methods that rely on heat; in such cases, careful bypass pumping and curing control are planned. Urban settings with paved drives and utilities favor trenchless methods because restoration costs can outstrip pipe work if full excavation is chosen. Conversely, a shallow line across undeveloped ground may be faster and economical to replace conventionally.

Pipe material guides expectations:

– Vitrified clay: common root intrusion at joints; typically good candidate for lining or bursting.

– Cast iron: corrosion and tuberculation; lining restores smoothness, but heavy scaling requires aggressive cleaning.

– PVC or ABS: fewer joints and smoother interior; localized damage may suit point repairs or short liners.

– Fiber-based legacy materials: structural degradation may push decisions toward bursting.

Hydraulic considerations matter. Any rehabilitation that reduces diameter must be evaluated against flow needs and slope. In many laterals, the reduced roughness of a new liner offsets a small diameter loss, yielding comparable capacity. Where flood events or high fixture loads demand more flow, bursting to maintain or increase diameter is compelling. Codes may also dictate minimum slope and materials, and many jurisdictions require permits and final inspection, sometimes with a pressure or low-pressure air test to confirm tightness.

Decision-making marries evidence and constraints. A typical path includes: verify defects by CCTV, quantify length and location, shortlist feasible methods, compare costs with restoration included, check permits and access, and schedule around household or business operations. A thoughtful plan can compress the onsite window to a single day while reducing risks of change orders. The result is a repair that addresses root causes rather than symptoms and sets the line up for decades of reliable service.

Pipe Relining Explained: Materials, Durability, and Performance

Pipe relining, most commonly executed as cured-in-place pipe, creates a new structural pipe inside the old one without extensive digging. The process begins with cleaning and inspection, followed by measurement to design liner thickness. A felt or fiberglass tube is saturated with resin and inserted into the host pipe. Depending on the system, the liner is inverted with water or air pressure or pulled in, then cured using hot water, steam, or ultraviolet light. After curing, technicians robotically reopen lateral connections and conduct a final CCTV inspection to verify smoothness, fit, and sealing at the ends.

Material selection shapes performance. Epoxy resins are often chosen for residential and commercial laterals due to strong adhesion and chemical resistance. Polyester and vinyl ester resins are also used in municipal and industrial contexts. Fiberglass reinforcement can increase stiffness with thinner walls, which helps maintain flow area. Design standards guide wall thickness based on soil loads, groundwater, and host pipe condition, aiming to resist buckling and long-term creep. The goal is a tight-fitting, corrosion-resistant, jointless pipe that arrests infiltration and denies roots a path into the line.

Durability data from utilities and testing labs indicate that properly designed and cured liners can offer multi-decade service life, often cited on the order of 50 years under typical conditions. Performance benefits include:

– Structural renewal that bridges cracks and offsets within design limits.

– Sealing of joints and small perforations to cut groundwater infiltration.

– A smooth interior surface that reduces friction and can stabilize capacity.

– Chemical resistance suited to household wastewater and many industrial effluents.

There are practical considerations to manage. Host pipes with severe deformation, long sags, or collapsed segments may be unsuitable for full-length lining without prior point repairs or excavation. Temperature control during curing affects final strength; installers monitor profiles to ensure resins reach target conversion. Temporary odors can occur during curing, so ventilation and communication are part of a responsible setup. After lining, accurate reinstatement of side connections is critical; robotic cutters create openings that are then smoothed to prevent debris catches.

For property owners, relining stands out for speed and limited surface impact. Typical residential projects can be completed in a day or two, including cleaning, lining, and reinstatement, with only small access points needed. The restored pipe resists common failure modes and reduces the likelihood of emergency backups tied to roots or infiltration. In many cases, it provides an effective balance of longevity, cost, and disruption, particularly where hardscapes or mature landscapes would be expensive to disturb.

Conclusion and Practical Planning Guide

Costs, schedules, and paperwork complete the decision picture. For residential laterals, lining often ranges from roughly $80 to $250 per linear foot, with total project costs commonly in the low thousands to low tens of thousands depending on length, access, and regional labor rates. Pipe bursting can fall in a similar band, especially when upsizing or navigating heavy damage. Open-trench replacement may appear cheaper per foot in soft soils, but surface restoration can double the final bill when driveways, patios, or landscaping are involved. Timewise, many trenchless jobs take a single day onsite after planning, whereas open-trench projects can stretch longer due to excavation, backfill, and restoration.

Permits and coordination help projects go smoothly. Many jurisdictions require a sewer permit, pre- and post-CCTV documentation, and an inspection. Work in the public right-of-way may trigger traffic control plans and specific restoration standards. Communicate with neighbors about temporary service interruptions, and schedule around low-use periods if possible. If your property includes large trees, consider consulting an arborist about root management after repair to extend the life of the renewed line.

Environmental and community impacts are also worth noting:

– Trenchless approaches typically reduce excavated spoil and construction waste.

– Less demolition means fewer truck trips for hauling debris and materials.

– Minimizing surface disturbance protects tree roots and established soils.

– Shorter work windows lessen noise and traffic impacts for the neighborhood.

To plan with confidence, assemble a simple checklist:

– Gather at least two proposals based on the same CCTV footage for apples-to-apples comparison.

– Ask about design assumptions: liner thickness, curing method, and how laterals will be reinstated.

– Confirm what restoration is included and what remains your responsibility.

– Verify permits, inspection steps, and warranty terms.

– Request a detailed schedule, including contingencies for weather or groundwater.

Summary for homeowners and property managers: trenchless sewer repair offers a practical way to renew failing lines without turning your yard or driveway into a construction site. Lining rehabilitates, bursting replaces, and both can deliver long service life when thoughtfully designed and competently installed. By combining careful diagnosis with a method tailored to your site, you can control costs, limit disruption, and restore reliability. A clear plan, rooted in evidence from the CCTV inspection and aligned with local permitting, will carry the project from problem to resolution with minimal drama.