Understanding Tankless Water Heater Installation Process

Outline:

– Installation: planning, permits, and safe setup from wall mount to commissioning

– Plumbing: layout, isolation, recirculation options, and water quality protection

– Sizing and Performance: matching temperature rise to flow demand

– Energy Efficiency: condensing vs. non‑condensing, controls, and operating habits

– Maintenance and Cost: descaling, inspections, repairs, and lifecycle budgeting

Installation: Planning, Permits, and Step‑by‑Step Setup

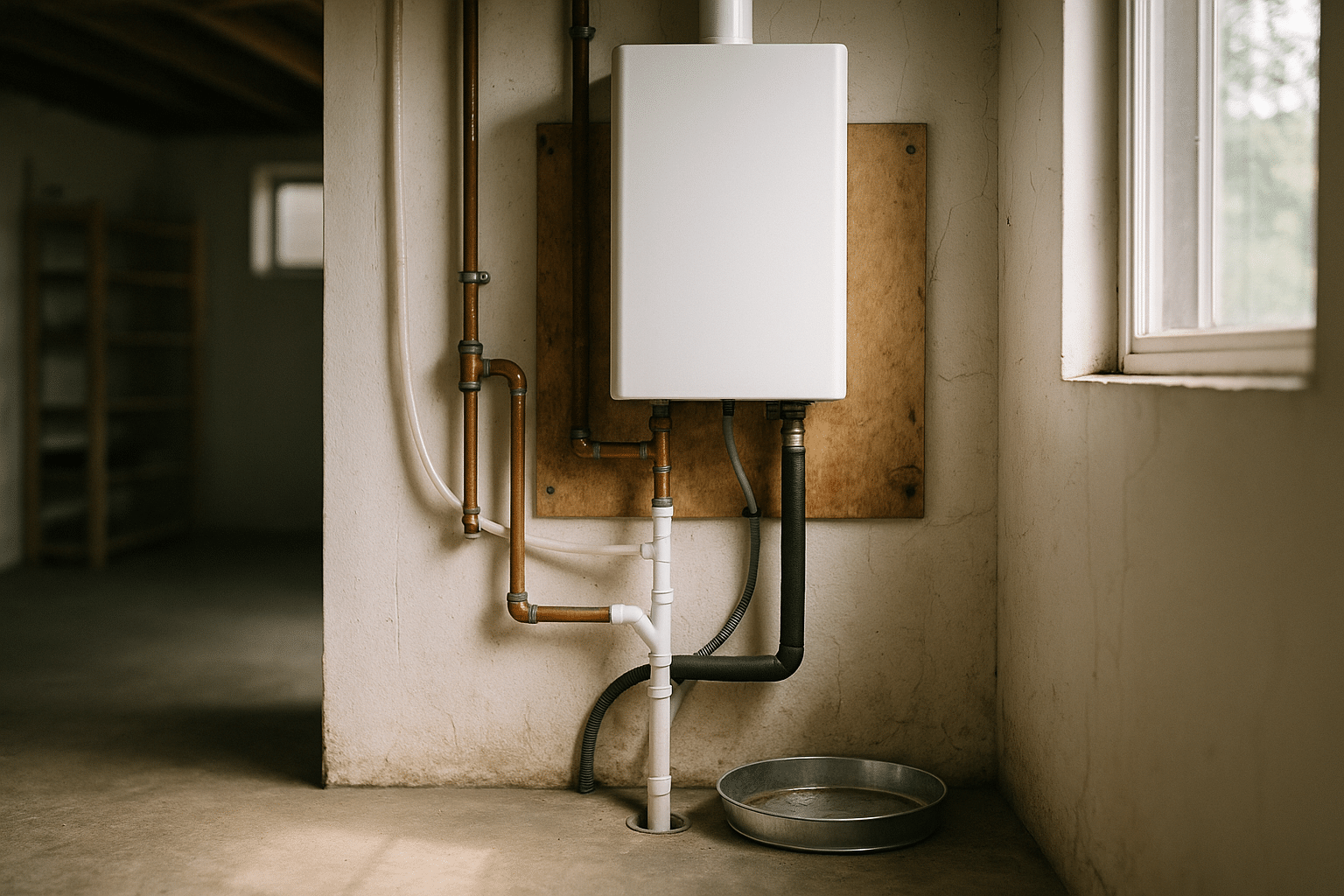

A tankless water heater can feel like swapping a bulky trunk for a sleek backpack—compact, efficient, and purpose built. Before hanging hardware, focus on planning. Start by confirming local code requirements, permit needs, and whether gas, propane, or electric service is available in the intended location. Choose a wall that supports the unit’s weight, has clearances for service, and provides straightforward routing for venting (for combustion models), condensate disposal (for condensing units), water lines, and power. Outdoor-rated models reduce venting complexity but add concerns about freeze protection; indoor models require dedicated venting and combustion air management.

Key steps you’ll take, often in this order, keep the job organized and safe:

– Verify gas line capacity or electrical service: many gas units call for 150,000–199,000 BTU/h supply and low-pressure drop; whole-home electric models may require multiple high-amperage circuits.

– Select venting path and materials: direct-vent, sealed combustion minimizes indoor air impacts; use listed pipe and follow equivalent length limits, slope, and clearances.

– Plan condensate handling for condensing units: slope the drain, add a neutralizer where required, and discharge to an approved receptor.

– Mount a backer board if studs are poorly aligned; ensure seismic strapping where required.

– Provide a nearby receptacle or hardwire per local code; avoid extension cords.

– Route cold and hot lines with isolation valves and service ports to simplify future maintenance.

Once rough‑in is complete, hang the heater on the bracket, connect plumbing, and pressure test the system. Venting should be assembled with manufacturer‑approved sealants and fittings, observing minimum clearances to windows, doors, and soffits. For gas, size the branch by length and total connected load; undersized lines cause ignition faults and reduced output. Electrical interlocks, if used with recirculation pumps, should be checked for correct operation. Commissioning includes purging air from lines, verifying gas pressure or voltage, setting the outlet temperature (120 °F is common for comfort and safety), and running multiple fixtures to confirm stable temperature under varying flows. Expect 4–8 hours for a straightforward retrofit, though complex venting or panel upgrades can extend the timeline. A final inspection—combustion analysis for gas units, leak checks, and code compliance—closes the loop and ensures the system is ready for years of service.

Plumbing: Layout, Recirculation, and Water Quality Safeguards

Thoughtful plumbing design is the difference between a responsive system and one that hesitates. Tankless heaters rely on flow to activate, so pipe sizing, fixture flow rates, and the presence of recirculation all matter. On the cold side, include a full‑port shutoff valve and a sediment filter if supply water carries grit. On the hot side, install an isolation valve. Between the two, add service ports (often called flush valves) that let you circulate a descaling solution without disassembling the unit. In closed systems with a check valve or pressure‑reducing valve, a small expansion tank on the cold inlet helps absorb thermal expansion and protect fixtures.

At the unit, a tidy manifold improves serviceability:

– Cold side: shutoff, union, service port, and optional sediment screen.

– Hot side: isolation valve, union, service port, and a union to a thermostatic mixing valve if you want finer anti‑scald control.

– Drainage: a hose‑bib drain or nearby laundry sink simplifies descaling and purges.

– Protection: water hammer arrestors at quick‑closing appliances reduce noise and stress on joints.

Recirculation, used to deliver faster hot water to distant fixtures, can be configured two ways. The most efficient is a dedicated return line from the far end of the hot‑water trunk back to the heater, paired with a high‑efficiency pump and an aquastat or smart control. Where a return line is absent, crossover valves at the far fixture allow the pump to use the cold line as a return path; this is simpler to retrofit but may cause brief lukewarm cold water at that tap. To curb energy losses with either approach, run the pump on occupancy, push‑button, or schedule rather than continuous mode, and insulate all accessible hot lines. Pay attention to minimum flow requirements: many heaters need roughly 0.4–0.6 GPM to fire, so pairing the system with ultra‑low‑flow aerators may require adjusting settings to avoid flicker or short cycling.

Water quality shapes reliability. Hard water accelerates scale formation on heat exchangers, restricting flow and forcing higher flame rates to maintain temperature. In regions above about 7 grains per gallon, consider a whole‑home softener, a template‑assisted crystallization device, or at least a dedicated scale inhibitor upstream of the heater. If you choose a softener, confirm that chloride levels stay within the appliance’s published limits. For well systems, iron and manganese filters protect small internal screens and valves. Add a simple leak sensor near the unit for peace of mind. When everything is laid out with clear isolation points, the system becomes easy to service and pleasant to live with—quick to deliver hot water and quiet in operation.

Sizing and Performance: Matching Heat to Flow Demand

The heart of sizing a tankless system lies in the relationship between flow rate, incoming water temperature, and the unit’s heating capacity. Every home has a “design temperature rise,” the difference between supply temperature at the tap (often 120 °F) and the coldest expected incoming water. In a northern climate with 40 °F supply, you’ll need an 80 °F rise; in milder regions at 60 °F supply, the rise is closer to 60 °F. The greater the rise, the fewer gallons per minute a given heater can deliver. That makes simultaneous use planning essential: two showers and a kitchen sink demand more capacity than a single bath.

Start with a quick inventory of likely concurrent loads:

– Shower: 1.8–2.5 GPM depending on the head.

– Bathroom faucet: 0.5–1.2 GPM with modern aerators.

– Kitchen faucet: 1.5–2.2 GPM, sometimes higher for pot filling.

– Laundry (warm): 1.5–2.0 GPM during fill cycles.

Add the expected simultaneous flows and choose a heater that can supply that total at your design temperature rise. If the result points to the upper end of a model’s capability, consider stepping up one size or adopting a recirculation strategy that reduces perceived delays without pushing continuous high flow.

Performance also depends on activation thresholds and modulation range. Many heaters ignite at roughly half a gallon per minute; below that, the burner may not fire, or the unit may cycle and cause brief temperature swings. Look for a wide modulation ratio so the heater can maintain a steady outlet temperature when a single low‑flow fixture is open. Pipe insulation and short runs further stabilize temperatures because less heat is lost between unit and tap, allowing lower flow rates to stay within the control window. At altitude, gas models typically derate—less oxygen means less heat output—so check the manual for capacity reductions above about 2,000–4,000 feet.

A few practical touches improve the user experience. Set the outlet temperature to 120 °F and add a thermostatic mixing valve if you routinely change setpoints, since mixing keeps delivery stable. Where “cold‑water sandwich” events are a concern (a momentary cool burst after a brief shutoff), recirculation controls or buffer tanks can smooth delivery without compromising efficiency. Finally, pair fixtures wisely: a low‑flow showerhead and an aerated bathroom faucet lower peak demand and let a moderately sized heater feel generous even during busy mornings.

Energy Efficiency: Getting More Hot Water from Every Unit of Fuel

Tankless water heaters reduce standby losses by heating water only when it is needed, and that design yields meaningful fuel savings over conventional storage tanks in many homes. Gas models fall into two broad categories. Non‑condensing units typically achieve uniform energy factors (UEF) around the low‑0.8 range, while condensing models that reclaim latent heat from exhaust often reach into the low‑ to mid‑0.9s. Electric point‑of‑use models can be highly efficient at the appliance level, though whole‑home units require substantial electrical capacity and may be more sensitive to regional energy prices. Real‑world studies and utility field data commonly show 10–30% fuel reductions compared with standard tanks, with the higher end more likely in households that avoid unnecessary recirculation and keep setpoints reasonable.

Several choices nudge performance higher:

– Prefer condensing gas units where venting and condensate disposal are feasible; cooler exhaust captures more heat.

– Insulate at least the first 10 feet of hot and cold lines at the heater to cut conductive losses.

– Use smart recirculation controls—push‑button, occupancy sensor, or short schedules—rather than running pumps constantly.

– Keep the setpoint modest (often 120 °F) and rely on a mixing valve when occasional higher temperatures are needed.

– Select WaterSense or similarly efficient fixtures to lower total hot‑water volume without sacrificing comfort.

Control strategies matter. Some units offer learning modes that build a schedule based on your habits; others provide external inputs for smart switches or home automation. Even without fancy controls, a simple timer matched to morning and evening peaks limits recirculation energy use while maintaining convenience. If you’re in a cold climate, insulating basement and crawlspace piping prevents heat from drifting into unconditioned areas. In warm climates, pipe insulation helps keep hot water from “preheating” spaces you pay to cool.

Efficiency also intersects with maintenance. Scale growth acts like a blanket over the heat exchanger, forcing higher firing rates to reach the same outlet temperature. An annual flush in moderate hardness regions—or more frequent service where hardness is high—restores performance. Check combustion settings during service; proper air‑fuel ratios on gas units not only reduce emissions but also improve efficiency and flame stability. Finally, consider the bigger picture: when replacing a failing tank, a right‑sized tankless system can lower utility costs and reduce mechanical room footprint, freeing storage space while trimming energy use in a way that’s practical and noticeable over the long term.

Maintenance, Safety, and Total Cost of Ownership

Like any hard‑working appliance, a tankless heater rewards routine care. Plan on an annual maintenance visit in average water conditions, with descaling intervals adjusted for hardness. Service typically includes cleaning or replacing inlet screens, inspecting the combustion chamber and fan (for gas models), confirming vent integrity, testing safety devices, and flushing the heat exchanger with a mild acid solution such as citric acid. Condensing models need condensate trap and neutralizer media checks; media cartridges slowly dissolve, so replacing them on schedule protects drains. For electric units, verify torque on electrical lugs and inspect for discoloration that may signal overheating.

Homeowners can handle several simple tasks between visits:

– Inspect around the unit for weeps or dampness; early detection prevents damage.

– Vacuum dust from louvers and keep the area clear for airflow.

– Test any leak alarms; replace batteries on a calendar cadence.

– Exercise isolation valves by opening and closing them fully a few times each year.

Costs vary by region and scope. A straightforward indoor retrofit that reuses existing gas capacity and suits a short vent run may fall in a moderate range, while projects requiring panel upgrades, long vent penetrations, or a new gas meter rise accordingly. Expect line‑item charges for permits, vent materials, gas or electrical work, isolation valve kits, and optional recirculation pumps or controls. Operating costs hinge on local energy prices and habits. Running a recirculation pump only when needed, insulating pipes, and keeping setpoints steady can materially lower bills. Over a 15–20 year service life—common for well‑maintained units—those incremental savings accumulate, often offsetting part of the higher upfront investment compared with a basic storage tank.

Safety threads through the entire lifecycle. Vent terminations must remain clear of snow, nests, and vegetation; blocked vents risk improper combustion. Carbon monoxide alarms near sleeping areas and on each floor are a prudent safeguard for any combustion appliance. In freezing climates, protect outdoor units with built‑in freeze protection and, where power outages occur, consider a battery backup to prevent burst piping. For homes on a private well, add a pressure gauge and relief checks to ensure stable operation. With a small toolkit, a calendar reminder for service, and a few smart operating habits, a tankless system delivers reliable hot water and a calm mechanical room—quiet, compact, and ready when you are.