Understanding the Process of Water Damage Restoration

Outline:

– Why speed matters and how water affects materials

– The restoration workflow from safety to rebuild

– Dehumidification explained: equipment, targets, and monitoring

– Mold removal: assessment, containment, and safe cleaning

– Costs, insurance, and long-term prevention strategies

The Urgency and Anatomy of Water Damage

Water damage begins quietly but escalates quickly. Within minutes, moisture starts seeping into porous materials; within hours, drywall softens, finishes blister, and subfloors swell. In one to two days, microbial activity can increase, odors emerge, and staining appears. The physics behind the scene is straightforward: water follows gravity, capillary action pulls it upward through materials, and vapor diffusion spreads moisture into adjacent spaces. This combination makes speed and strategy central to any successful restoration effort. The goal is not only to remove standing water but also to arrest hidden moisture migration and stabilize the indoor environment before materials cross the threshold from salvageable to compromised.

Understanding how different materials behave helps set priorities. Drywall, insulation, and untreated wood absorb readily and can lose structural integrity when saturation persists. Engineered flooring can delaminate, while solid hardwood may cup or crown as fibers expand unevenly. Masonry resists liquid water but can harbor moisture in voids that later diffuses, causing efflorescence or secondary damage. Electrical systems and fixtures require careful inspection because trapped moisture raises safety risks even after surfaces look dry. A sensible triage asks: What is wet? How wet is it? How long has it been wet? The answers guide both removal and salvage decisions.

Immediate actions reduce long-term fallout and protect health. Practical priorities include:

– Shut off the water source and, if needed, the power to affected circuits.

– Document conditions with photos and moisture readings to support decisions and potential claims.

– Extract standing water and separate wet contents to promote airflow.

– Ventilate cautiously; when outdoor air is humid, rely on controlled dehumidification rather than open windows.

– Monitor for temperature and relative humidity changes to prevent secondary damage like warping or corrosion.

These steps are less about heroics and more about momentum. Each hour of decisive action prevents days of repair, and in many cases, preserves finishes and structures that might otherwise be lost.

Step-by-Step Restoration Workflow: From Safety to Rebuild

Successful restoration follows a disciplined sequence that balances urgency with verification. Step one is safety: confirm that power to affected areas is controlled, ensure the building is structurally stable, and assess air quality. Step two is source control—repair a burst pipe, patch a roof opening, or divert storm water. Step three is assessment and documentation, using moisture meters and thermal imaging to map the spread. This map becomes the game plan for extraction, drying, and selective removal. Skipping documentation risks missed cavities and makes it harder to prove progress, so careful notes and measurements matter as much as pumps and fans.

Water removal is the quickest win. High-volume extraction removes far more moisture per hour than air movement alone, shortening the drying timeline. Once standing water is gone, technicians open the system to airflow by removing baseboards, drilling weep holes where appropriate, or lifting edges of flooring. Materials that cannot be reliably decontaminated—saturated insulation, swelling particleboard, and contaminated carpet in unsanitary events—are removed to prevent odors and microbial growth. Cleaning follows, targeting soils and residues left by the water. Where contamination is a concern, appropriate cleaning agents and rinsing protocols reduce risk while preparing surfaces for drying.

Drying and monitoring are the heart of the process. Air movers create evaporation at wet surfaces, while dehumidifiers capture the resulting moisture from the air. Progress is tracked through daily measurements: surface moisture content, ambient temperature, and relative humidity. Adjustments are routine—relocating equipment to new wet zones, tweaking airflow to avoid dead spots, and sealing off unaffected rooms to maintain an efficient drying chamber. When readings confirm that materials have returned to normal moisture content for the climate and construction, the space transitions to rebuild. The rebuild phase addresses repairs such as replacing drywall, refinishing floors, and repainting. Useful reminders:

– Prioritize verification over assumptions; hidden cavities are common culprits.

– Keep detailed logs to justify each decision and change in strategy.

– Coordinate with other trades to avoid rewetting or reintroducing dust and debris.

This methodical rhythm—assess, act, verify, adjust—turns a chaotic scene into a controlled project with a predictable end point.

Dehumidification: Drying Science, Equipment, and Metrics

Dehumidification is the backbone of structural drying, transforming evaporation into permanent moisture removal. Without it, air movers simply shuffle water from surfaces into the air and back onto cooler materials. The key variables are temperature, relative humidity (RH), and vapor pressure. Warmer air holds more moisture; lowering RH increases the vapor pressure gradient so water leaves materials and enters the air. Practical targets often aim for RH in the 40–55 percent range during active drying, with temperatures moderate enough to encourage evaporation without causing uncomfortable heat buildup or condensation in cool zones.

Two main technologies dominate: refrigerant dehumidifiers and desiccant systems. Refrigerant units cool moist air so water condenses and drains away; they work efficiently in typical indoor temperature ranges and are commonly used in homes. Desiccant systems pass air across moisture-attracting media and can achieve very low humidity even in cooler conditions, which helps with dense materials and cold-weather projects. An effective setup uses air movers to push dry air across wet surfaces, then routes the moisture-laden air back to dehumidifiers for removal. The arrangement minimizes dead zones and maintains circulation without blasting directly at fragile finishes. Tips for placement and operation include:

– Create a closed drying environment by isolating affected rooms with doors or plastic barriers.

– Position air movers to sweep along surfaces, not straight into them, to prevent scattering debris.

– Check for short-cycling; if dry air immediately re-enters a dehumidifier, redistribute equipment to reach wet areas first.

– Track dew point and grains-per-pound (or an equivalent moisture metric) to quantify progress beyond RH alone.

Monitoring separates wishful thinking from actual drying. Daily logs should capture ambient conditions and material moisture content at consistent locations. If readings stagnate, troubleshoot: insufficient dehumidifier capacity, hidden moisture behind vapor barriers, or cold surfaces causing local condensation. Adjustments might include removing wet baseboards, opening cavities, increasing capacity, or slightly raising temperature to keep evaporation steady. Dehumidification is as much strategy as machinery. The principle is simple—encourage water to leave materials and capture it from the air—but execution requires attention to airflow paths, temperature balance, and the ever-changing moisture map of the building.

Mold Removal: Assessment, Containment, and Clearance

Mold is a moisture problem wearing a biological mask. It thrives where water lingers and nutrients are available, colonizing drywall, wood, carpet, and dust. Prompt, methodical removal protects both indoor surfaces and indoor air quality. Start with assessment: determine the extent of growth, active moisture sources, and affected materials. Visual inspection is the foundation; supplemental testing can be useful in complex or disputed cases but is not a substitute for finding and fixing moisture. If liquid water or high humidity remains, address that first. Drying stabilizes the environment and prevents new growth while you plan remediation.

Containment keeps spores from migrating. For moderate to larger projects, establish a work zone with plastic sheeting, zipper access, and negative pressure vented outdoors through appropriate filtration. Workers use protective gear suited to the task. Cleaning methods match material type: non-porous surfaces are typically cleaned by HEPA vacuuming and damp wiping; semi-porous materials like framing lumber may require HEPA vacuuming followed by wire brushing and wiping; heavily colonized porous materials such as saturated drywall are removed and bagged for disposal. During active cleaning, a HEPA-filtered air scrubber in the containment can reduce airborne spores, improving both visibility and cleanliness of the site.

Verification ensures the job is truly complete. A thorough approach includes:

– Confirming the moisture source is corrected and materials are at normal moisture levels.

– Inspecting for visible dust, debris, and staining; clean work areas should look and feel dust-free.

– Running the air scrubber long enough after cleaning to reduce residual particles.

– Performing clearance checks, which may include visual criteria and, when warranted, air or surface sampling against normal indoor/outdoor comparisons.

Mold removal succeeds when occupants regain a clean, dry space, rather than when a surface merely looks improved. Keep in mind that prevention is part of remediation. Maintain RH near or below 50 percent, ventilate bathrooms and kitchens, insulate cold surfaces that sweat, and respond quickly to leaks. Mold is persistent but not mysterious: control moisture, and you control the outcome.

Costs, Insurance, and Prevention: Making Smart Decisions

Decision-making during water damage is a blend of facts, priorities, and timing. Costs vary with the size of the affected area, the category of water (clean, moderately contaminated, or unsanitary), material types, and how long the water has been present. Extraction and drying are generally less expensive than reconstruction, so accelerating the early phase saves money. Transparent estimates should outline labor, equipment, expected duration, and potential contingencies such as hidden cavities or required material removal. Daily monitoring notes justify charges and help you evaluate progress in real time.

Insurance can be a valuable partner when coverage applies. Sudden and accidental events are often handled differently than exterior flooding, which may require separate policies. Practical steps include:

– Report the loss promptly and keep a log of conversations, dates, and decisions.

– Photograph affected areas before and during mitigation, capturing meter readings and equipment placement.

– Preserve samples of removed materials if requested by the adjuster.

– Avoid discarding items until you receive guidance, unless they create a health or safety hazard.

Regardless of coverage, choose providers who communicate clearly, share daily readings, and invite questions. A well-regarded contractor explains why each step matters and what success will look like in measurable terms.

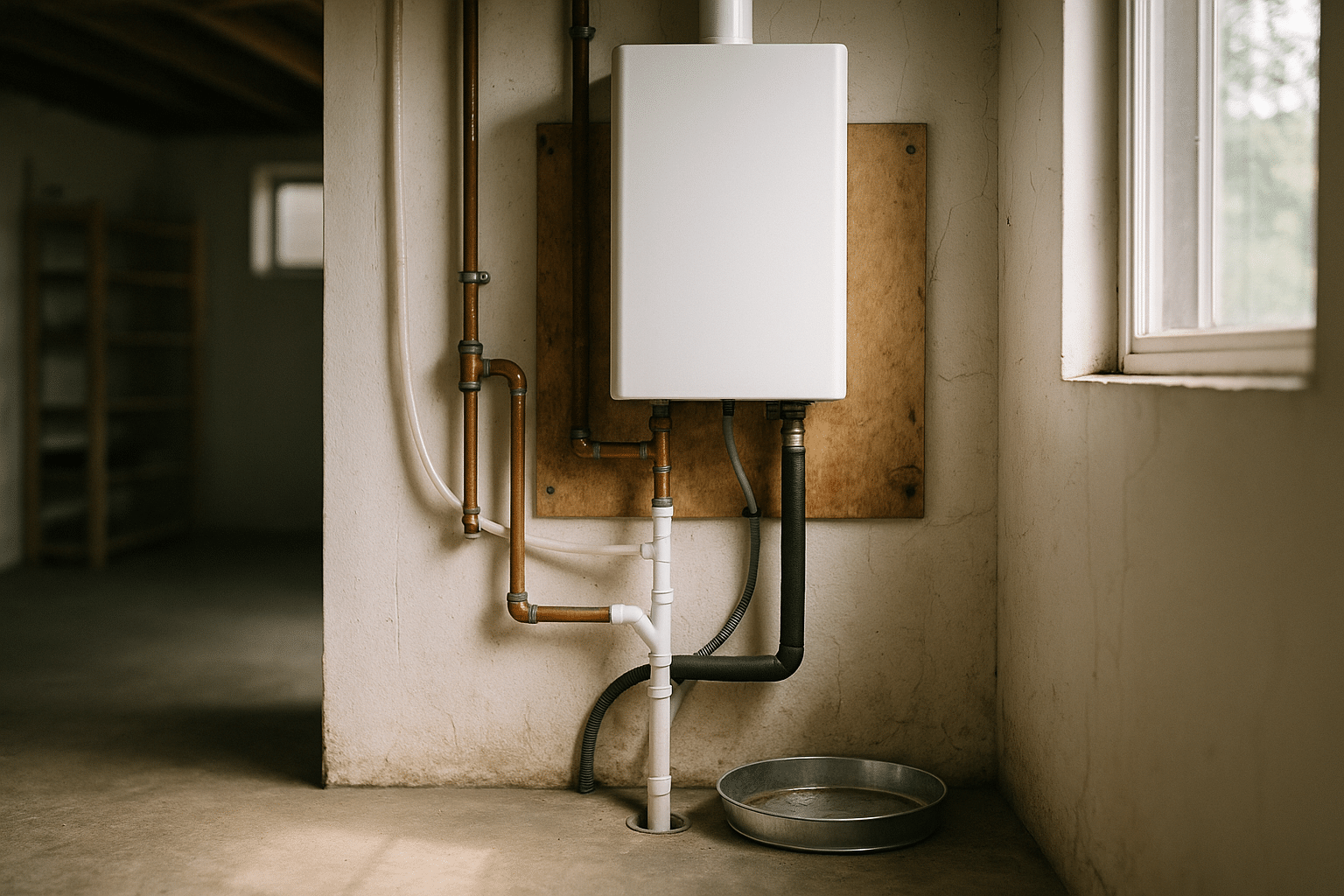

Prevention is the long-term dividend of a difficult week. Simple habits reduce future risk: maintain gutters and downspouts, slope soil away from foundations, insulate cold water lines to prevent condensation, and install leak sensors near appliances, water heaters, and under sinks. Consider shutoff valves that stop supply lines during detected events. Indoors, aim for steady RH in the 30–50 percent range and use exhaust fans that vent to the exterior. Address minor leaks the day they appear, not the week after. A final thought: water problems are rarely solved by a single fix but often by a small system of good decisions. When you combine timely action, controlled dehumidification, and careful mold management, you turn water from a crisis into a contained and recoverable project.