Advantages of Using Silicone Roof Coatings for Longevity

Introduction & Outline: Why Silicone Roof Coatings Elevate Roofing and Waterproofing

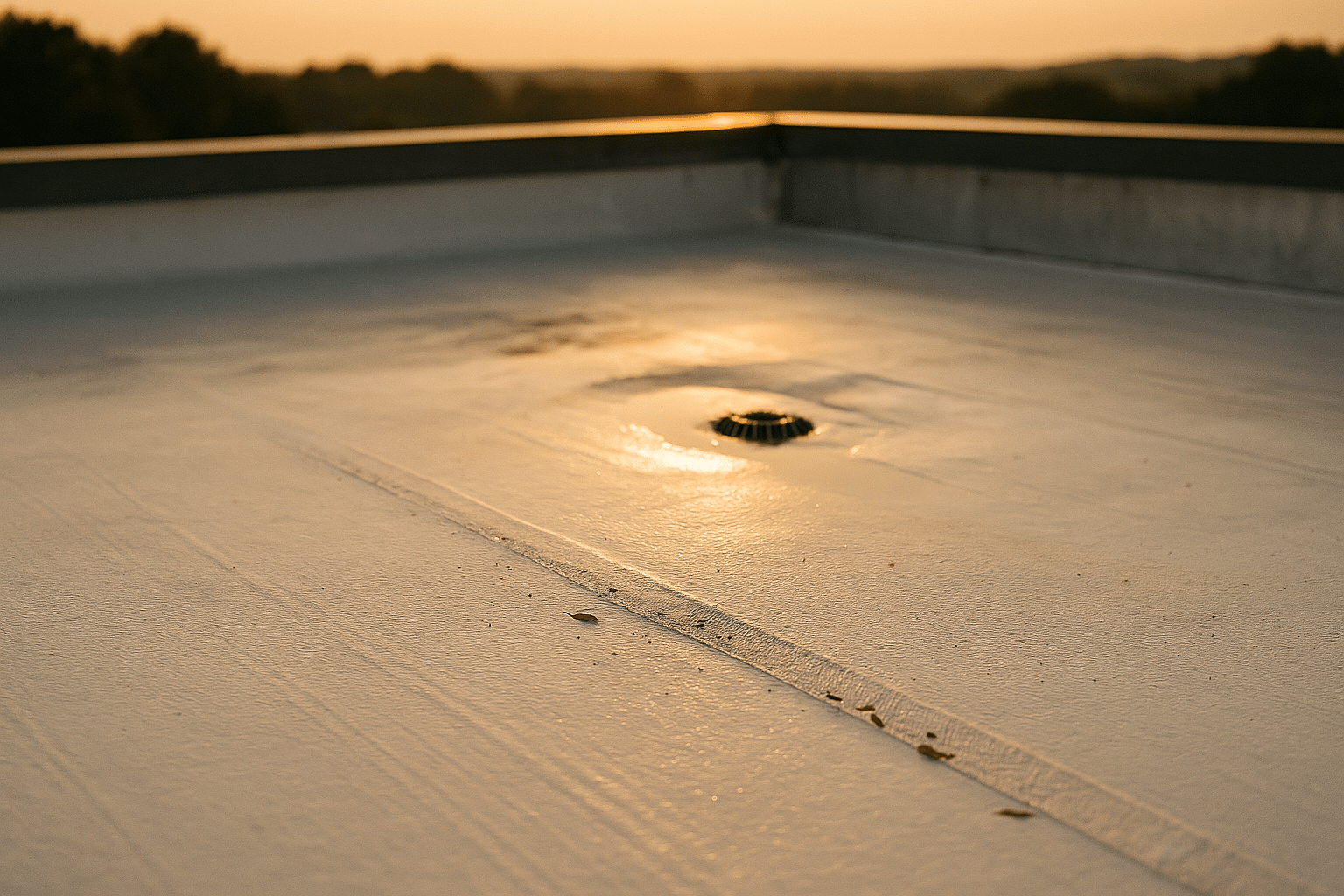

Roofs quietly carry the weight of every season—sun-scorched afternoons, freeze–thaw cycles, wind-driven rain—and still have to keep interiors dry, efficient, and comfortable. Silicone roof coatings offer a practical pathway to extend service life without the disruption of full tear-offs, especially on large flat and low-slope assemblies. This article links three pillars—roofing fundamentals, coating chemistries, and waterproofing details—so you can evaluate whether a silicone system aligns with your building’s goals for durability, energy performance, and maintenance predictability.

What follows is a clear roadmap to guide decision-making from inspection to installation and long-term care:

– Roofing context: substrates, climate pressures, and the physics that age a roof.

– Coating comparisons: silicone versus acrylic, polyurethane, and asphaltic options, with performance trade-offs.

– Waterproofing focus: how details, reinforcement, and drainage choices prevent leaks where they most often start.

– Implementation: surface prep, application checks, quality assurance, maintenance, and recoat planning.

– Value and risk: lifecycle cost, energy impacts, and what can go wrong if steps are skipped.

By the end, you’ll be able to answer crucial questions: Does my existing membrane or metal roof suit a silicone overlay? Which climates see the strongest gains from high reflectivity and ponding-water tolerance? How do thickness, adhesion, and reinforcement influence longevity? And how do I document performance so the roof’s story is written in data, not guesswork? Whether you manage one small building or a portfolio, this outline equips you to translate options into a practical, defensible plan.

Roofing Systems 101 and Where Silicone Fits

Not all roofs age the same. Single-ply membranes (such as EPDM, TPO, and PVC), asphaltic systems (built-up or modified bitumen), spray polyurethane foam, and metal panels each respond differently to ultraviolet exposure, thermal cycling, hail, and standing water. Silicone coatings fit particularly well on low-slope assemblies where reflectivity and moisture resistance can reduce heat stress and mitigate leak risk. In many climates, cool reflective surfaces can lower peak roof temperatures by 30–50°F compared with dark surfaces, easing thermal movement at seams and curbs.

The physics of degradation is simple but relentless. UV radiation embrittles polymers, daily temperature swings fatigue seams, and wind drives water into tiny discontinuities. Where drainage is marginal, ponding accelerates failure in systems that are not water-immersive. Silicone chemistry remains stable under prolonged UV and is inherently hydrophobic, so it resists softening under standing water better than many alternatives. Typical silicone topcoats deliver solar reflectance around 0.80 or higher and thermal emittance near 0.90, helping manage cooling loads, especially in sunbelt regions.

Compatibility and preparation determine outcomes. A coating is only as strong as what it adheres to. Successful projects begin with a thorough condition assessment: infrared or capacitance moisture scans to map wet insulation, core cuts to confirm substrate type and thickness, and pull tests to verify adhesion. Many EPDM and asphaltic roofs accept silicone after cleaning and selective priming, while certain thermoplastics may require specialized primers to lock in adhesion. Typical dry film thickness targets range from about 20–40 mils, adjusted by climate, exposure, and warranty goals set by the specifier.

Three practical examples illustrate fit: a coastal warehouse with salt-laden winds benefits from silicone’s UV and moisture resilience; a desert retail plaza sees meaningful heat reduction from high reflectivity; a northern facility with freeze–thaw cycles leverages elasticity to accommodate movement around penetrations. In every case, slope-to-drain and detail integrity matter as much as the coating itself. The roof is a system, and silicone works best when it complements sound substrate repairs, smart drainage, and verified adhesion.

Coating Chemistries Compared: Silicone, Acrylic, Polyurethane, and Asphaltic Options

Choosing a coating is a trade-off exercise shaped by climate, substrate, foot traffic, and budget. Silicone, acrylic, polyurethane (aromatic or aliphatic), and asphaltic aluminized products each bring distinct strengths and limitations. Understanding these differences prevents mismatched expectations and helps specifiers tune performance to real-world conditions instead of marketing claims.

Silicone stands out for UV stability and ponding-water resistance. It generally keeps flexibility over time and maintains reflectivity even after seasons of exposure. Dirt pickup can be higher than on some hard-finish coatings, so periodic washing helps preserve reflectance. Acrylics are cost-effective and highly reflective, yet they dislike continuous immersion; ponding can lead to premature softening or blistering if drainage is poor. Polyurethanes offer robust abrasion and chemical resistance with strong tensile properties; aliphatic variants resist UV better than aromatic ones and may be used as durable topcoats over base layers. Asphaltic aluminized coatings provide corrosion protection on metal and reflect radiant heat, but they usually lack the elongation and ponding tolerance of silicone or high-grade polyurethane.

Key trade-offs to weigh include:

– Water exposure: silicone tolerates ponding; acrylics typically require positive drainage; polyurethanes vary by formulation.

– Movement and abrasion: polyurethanes shine under foot traffic and mechanical abuse; silicone and acrylics are more elastic than many asphaltic products.

– Reflectivity and aging: silicone and acrylics start high; silicone tends to retain reflectance longer under intense UV.

– Application windows: silicone can often cure in wider humidity ranges; acrylics prefer warmer, drier conditions; polyurethanes may require careful solvent and ventilation controls.

– Cost and complexity: acrylics can be economical where drainage is reliable; silicone offers value in ponding-prone settings; polyurethanes add toughness at higher material complexity.

As for numbers, many silicone systems target elongation in the 150–300% range with tensile strengths commonly in the hundreds of psi, sufficient to bridge minor movement. Acrylics can show comparable initial elongation but lose performance faster if submerged. Polyurethanes often deliver higher tensile strengths and abrasion resistance, which can be valuable around access paths or service corridors. Cure times vary: silicones often skin quickly and achieve through-cure within a day depending on humidity and film build, while acrylics may need extended dry periods between coats. The right choice aligns chemistry with the roof’s realities: is the deck flat with occasional birdbaths, or does it shed water fast? Are there chemical exposures from nearby vents? Will maintenance crews frequently traverse the surface? The clearest path to longevity matches material behavior to these site-specific truths.

Waterproofing in Practice: Details, Reinforcement, and Drainage

Most leaks originate at details, not field areas. Industry surveys commonly attribute the majority of failures—often cited at well over half—to terminations, flashings, seams, penetrations, skylight curbs, and parapet interfaces. A silicone topcoat can seal the field brilliantly, but overlooking a cracked pitch pan or loose counterflashing invites recurring problems. Effective waterproofing is a choreography of reinforcement, slope, and redundancy that anticipates how water really moves on your roof.

Start with drainage. Even a reflective, hydrophobic surface works harder when water lingers. Verify that drains, scuppers, and gutters are clear and sized appropriately; correct low spots by adding tapered insulation or localized patches to promote flow. Where minor ponding is unavoidable, silicone’s tolerance is helpful, but standing water should not be viewed as harmless. It concentrates debris, increases live load, and stresses coatings around edges where film thickness might be thinnest.

Reinforcement turns vulnerable details into durable transitions. Polyester fabric embedded in a base coat around seams, inside corners, and protrusions spreads stress and resists cracking. Many crews reinforce the first 6–12 inches up parapet walls and around curbs before applying full-field coats. Mastics and sealants compatible with the coating system can tackle small gaps, but larger voids or deteriorated substrates demand proper repairs before coating. Penetrations—HVAC supports, conduit clusters, vent stacks—benefit from boot-style reinforcement and generous radiused fabric to avoid sharp stress points.

Quality control tightens the seal. Use wet-mil gauges during application to confirm target film builds; dry film thickness later verifies coverage. Pull tests at representative locations confirm adhesion to each substrate type encountered. Where conductive primers or metal decks are present, holiday detection can identify thin spots or pinholes. Finally, a water test—carefully conducted without overloading the deck—can validate that critical transitions shed water as intended. The waterproofing goal is not perfection but controlled redundancy: if the first line of defense is nicked, the second holds, and the third still directs water to a drain. In that layered strategy, silicone is a reliable surface armor, but the hidden strength lies in disciplined detailing.

Installation, Maintenance, ROI, and Conclusion for Building Owners and Managers

Durability begins before the first gallon is opened. A methodical process reduces risk and sharpens returns: inspect, test, repair, and only then coat. Map wet insulation with infrared at dusk, confirm with core cuts, and replace saturated areas so trapped moisture does not drive blisters later. Clean aggressively—pressure wash within manufacturer limits, degrease around vents, and remove friable surfacing. Conduct adhesion tests on every representative substrate, and specify primers where needed. Only after these steps should crews reinforce details, lay down base coats, and apply topcoats to the specified thickness.

Application options vary. Rolling can deliver consistent film builds on small to mid-size roofs; airless spray accelerates production on larger areas but demands wind discipline and masking. Record environmental conditions—temperature, humidity, and roof surface temperature—because cure rates and recoat windows depend on them. Document everything with photos and thickness readings; that record becomes invaluable when planning maintenance or assessing recoat timing years later.

Maintenance is light but non-negotiable. Plan semiannual inspections plus checks after severe storms. Keep drains clear, remove debris that can stain or abrade the surface, and reseal incidental cuts promptly. Many silicone roofs can be renewed by cleaning and recoating after a service interval, which avoids landfill waste from premature tear-offs. Reflective surfaces can trim cooling energy use, sometimes in the 10–30% range for roof-dominated buildings in hot climates, although actual savings hinge on insulation levels, HVAC efficiency, and occupancy patterns. Just as important, lowering peak roof temperatures reduces thermal stress that shortens service life.

From a lifecycle perspective, the value proposition rests on avoided tear-off costs, reduced disruption, and the ability to recoat. When budgets are tight or operations cannot tolerate a full replacement, silicone systems offer a path to extend life while improving weatherability. They are not a cure-all: poor drainage, hidden moisture, or skipped prep will erode gains. The conclusion for facility teams is practical and focused: match chemistry to climate and substrate, fix details first, measure what you install, and commit to light but regular care. Do that, and a silicone roof coating becomes more than a shiny finish—it becomes a measured strategy for longevity, resilience, and predictable ownership costs.