Understanding the Process of Roof Replacement Services

Overview and Outline: Why Roof Replacement Matters

Your roof is the quiet guardian of your home, working through sun, wind, and storm without asking for applause. When it nears the end of its lifespan, replacement stops being a cosmetic decision and becomes a matter of durability, energy performance, and protecting the structure beneath. A timely, well‑planned roof replacement can prevent moisture damage, stabilize indoor temperatures, and restore curb appeal in one coordinated project. To help you move from uncertainty to clarity, this article mixes practical details with plain‑spoken comparisons and a touch of storytelling, so you can picture the process before a single shingle is lifted.

Outline at a glance:

– Understanding the roof system: structure, weatherproof layers, and ventilation

– Shingles and alternatives: materials, lifespans, costs, and performance ratings

– The replacement timeline: preparation, tear‑off, installation, cleanup, and inspections

– Working with contractors: bids, contracts, warranties, and communication

– Conclusion: turning decisions into a well‑executed plan

Why it matters now: small leaks rarely stay small. Water intrusion can travel along rafters, wet insulation, and spur mold in as little as 24–48 hours if conditions allow. Proper attic ventilation (balanced intake and exhaust) can reduce attic temperatures by roughly 10–25°F in summer, easing the load on cooling systems and helping shingles age more gracefully. A new roof, selected for your climate and installed to code, also supports resale value and may help with insurance acceptance. The goal is not just a fresh surface, but a resilient system—from deck to ridge—that manages water, air, and heat as a team.

Roofing Systems 101: Structure, Weatherproofing, and Ventilation

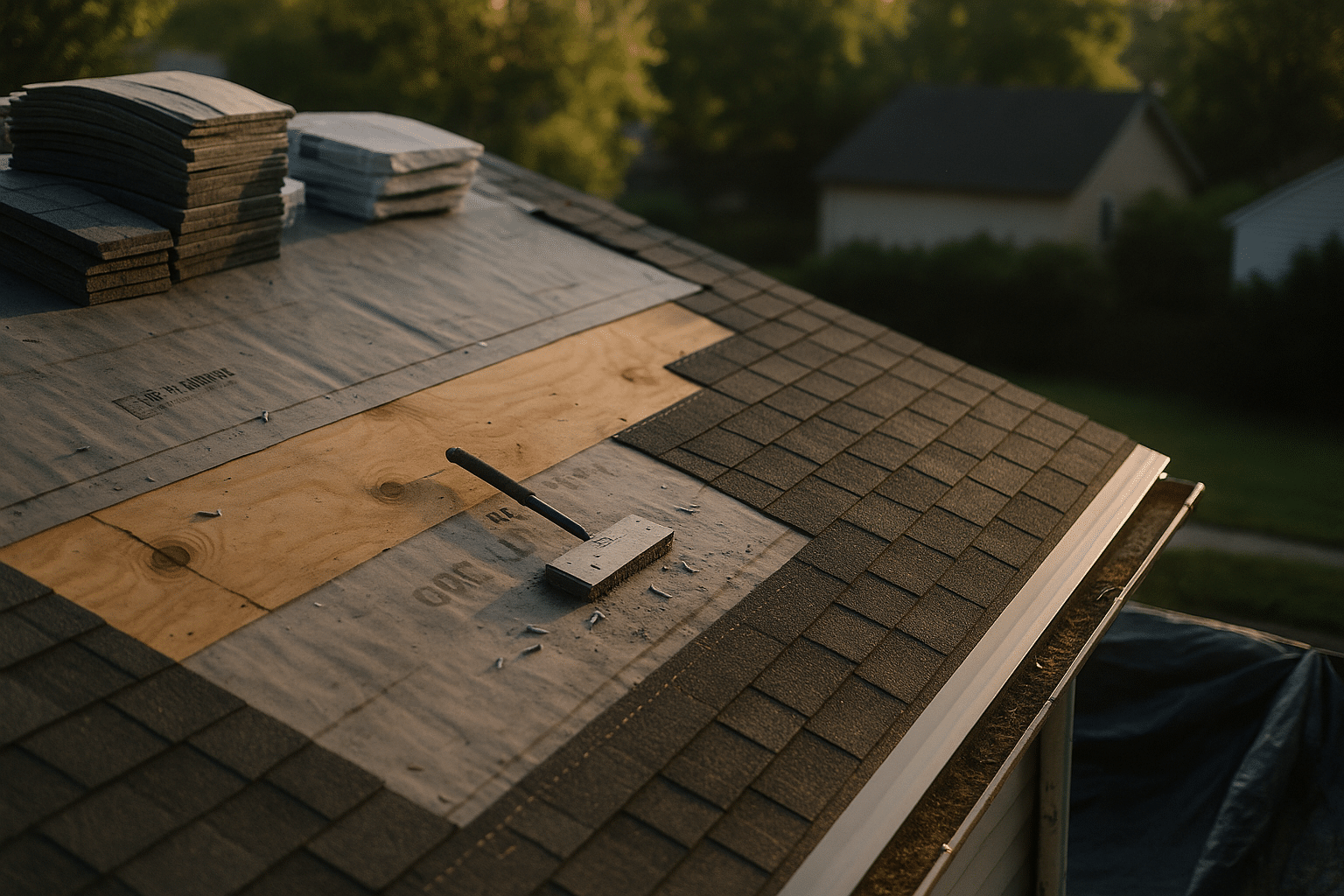

Think of a roof as a layered system rather than a single product. The structure begins with the framing—rafters or trusses—topped by the deck, typically oriented strand board or plywood. Deck thickness varies with span and code, with 7/16 inch OSB common in many markets, though heavier panels may be specified for higher loads. Slope is expressed as rise over run (for example, 6:12), affecting how quickly water sheds and which materials are appropriate. Valleys, hips, and ridges create transitions that require extra attention in both design and installation. Fasteners, too, matter: corrosion‑resistant nails matched to the deck and material help the entire assembly resist wind uplift.

Above the deck, weatherproofing layers do the heavy lifting. Underlayment—traditionally asphalt‑saturated felt, now often a synthetic—acts as a secondary water‑shedding layer. In cold climates, self‑adhering ice‑barrier membranes are commonly installed at eaves and valleys to counter ice dams, which can force meltwater backward under shingles. Flashing—step, counter, valley, and apron—directs water away from vulnerable transitions such as chimneys, walls, and skylights. Drip edge at the eaves and rakes closes gaps at the perimeter so water drips cleanly into the gutter rather than wicking into wood. Starter courses and ridge caps complete the envelope, preventing wind from getting under the first and last courses.

Ventilation is the quiet partner in roof longevity. Building codes often cite 1 square foot of net free vent area for every 150 square feet of attic floor (1:150), or 1:300 when balanced intake and exhaust are verified, though local rules vary. The principle is simple: cool, dry air enters at soffit vents and warm, moist air exits through ridge vents or other exhaust points, minimizing condensation in winter and heat buildup in summer. Baffles keep insulation from choking airflow at the eaves, and air sealing the ceiling below reduces humid air migration into the attic. Together, these measures protect the deck, prevent nail corrosion, and help shingles maintain their rated performance.

Red flags that suggest a system, not just a surface, needs attention:

– Soft or spongy decking underfoot after tear‑off

– Rusted or paint‑sealed flashing around penetrations

– Insufficient intake vents compared to exhaust at the ridge

– Chronic attic condensation or frost on nails in winter

– Multiple shingle layers hiding past leaks or structural issues

Shingles and Alternatives: Lifespan, Cost, and Performance Compared

Shingles remain a popular choice because they balance cost, versatility, and acceptable lifespans for many climates. Asphalt‑based products come in various profiles and weight classes, with dimensional designs adding shadow lines and thicker mats for improved wind resistance. Their typical service life ranges from roughly 15–30 years when installed correctly and ventilated well. Moving up the durability ladder, metal panels or shingles offer long service lives—often cited around 40–70 years—strong wind resistance when properly fastened, and lighter weight per square foot than tile. Wood shakes provide a distinctive, natural look with moderate insulation value, though they require diligent maintenance and are restricted in some fire‑prone regions. Clay and concrete tiles deliver exceptional longevity—commonly 50–100 years—but add substantial weight that must be engineered into the structure. Synthetic composites aim to mimic slate or shake aesthetics while reducing weight and maintenance, with lifespans often quoted in the 30–50 year range.

Key metrics to compare:

– Fire rating: Class A is the most fire‑resistant rating for roof coverings

– Wind rating: many modern shingles are rated for 110–130 mph when installed to spec; metal systems can exceed these ratings with correct anchoring

– Impact resistance: Class 3 or Class 4 ratings indicate greater resilience to hail

– Weight: approximate ranges per square foot—metal ~1–1.5 lb, asphalt ~2–4 lb, wood ~3–4 lb, tile ~6–12 lb (varies by product)

– Cost (material + typical labor, highly location‑dependent): asphalt roughly $4–$8 per sq ft; metal $7–$14; wood $7–$12; tile $10–$20; synthetic $8–$15

Climate fit examples:

– Hot, sunny regions: reflective “cool” finishes or lighter‑colored shingles help reduce heat gain

– Coastal or high‑wind zones: enhanced wind ratings, corrosion‑resistant fasteners, and sealed seams are priorities

– Cold climates with snow: robust ice‑barrier membranes at eaves/valleys and steeper slopes to shed snow more effectively

– Hail‑prone areas: products with impact‑resistance ratings and comprehensive installation that includes properly seated fasteners

– Wildfire‑exposed regions: materials with a Class A fire rating and ember‑resistant attic vents

Beyond performance, consider sustainability and aesthetics. Some shingles incorporate recycled content, and certain products can be recycled at end of life, though availability varies by region. Metal’s recyclability is well established, and its relatively light weight can be an advantage for existing structures. Tile and slate have long lifespans that spread their embodied energy over decades. If you anticipate future rooftop solar, ask about load capacity, flashing options, and how a given roofing profile pairs with mounting hardware. The right choice is the one that fits your climate, budget, maintenance appetite, and long‑term plans for the home.

The Roof Replacement Timeline: From Planning to Final Inspection

A successful roof replacement begins before a crew arrives. Start with a thorough inspection—either from the attic (looking for daylight at penetrations, staining, or damp insulation) or by a qualified professional on the exterior. Expect a written proposal that specifies materials, underlayments, flashing details, ventilation approach, and disposal plans. Permits may be required; reputable crews typically handle the application and post any necessary notices. Weather dictates scheduling, so allow for a flexible window if storms are in the forecast. Most single‑family homes can be completed in 1–3 working days once the crew starts, but complex roofs, multiple layers, or deck repairs can extend that timeline.

The on‑site process follows a logical sequence. Protection comes first: tarps over landscaping, plywood guards where needed, and magnet bars staged for cleanup. Tear‑off removes old shingles and underlayment down to the deck so hidden issues are visible. Decking is repaired or replaced where soft spots or rot appear; skipping this step invites future leaks. Ice‑barrier membranes and synthetic underlayment are installed with correct overlaps and fastener spacing. Flashing is replaced—not painted over—and integrated with step flashing at sidewalls, apron flashing at penetrations, and properly woven or metal‑lined valleys. Shingles or other coverings are then laid according to manufacturer patterns, with starter strips at eaves and hip/ridge caps at the roof’s peaks. Ventilation components—baffles, intake vents, and ridge exhaust—are balanced to the plan. Finally, the site is cleaned, including magnet sweeping for stray nails and removal of debris to a dumpster.

Simple preparations you can make:

– Clear driveway access for the delivery truck and dumpster

– Move patio furniture, grills, and vehicles out of the fall zone

– Take down delicate wall art or ceiling fixtures that could rattle

– Cover attic storage to keep dust off belongings

– Plan for noise; pets and remote work may need temporary accommodations

Quality checks before final payment include verifying new flashing at all penetrations, confirming underlayment coverage at eaves and valleys, checking ridge vent continuity, and ensuring gutters were cleared of granules and debris. Request documentation: permit sign‑off where applicable, product and workmanship warranties, and a final invoice that reflects any approved change orders. A brief walk‑around with the crew lead to discuss what was found and fixed is time well spent—you’ll better understand your roof and the value of the work completed.

Choosing and Managing Contractors: Bids, Contracts, Warranties, and Communication

The right contractor brings craftsmanship and predictability to a project that can otherwise feel chaotic. Start by confirming core credentials: an active license if required in your jurisdiction, general liability and workers’ compensation insurance, and a physical office address. Ask for recent, local references and—when possible—addresses you can drive by to view completed work from the street. Online reviews provide context, but nothing replaces a detailed, written proposal and a conversation where your questions are answered clearly. Avoid high‑pressure tactics; your roof should be replaced on your timeline, not someone else’s quota.

Gather at least three comparable bids and audit them line by line. Look for:

– Tear‑off scope (full removal vs overlays) and deck repair allowance

– Underlayment type, ice‑barrier placement, and flashing replacement plan

– Ventilation approach, including intake and exhaust balance

– Fastener specifications and slope‑specific installation methods

– Site protection, daily cleanup, and magnetic nail sweeping

– Disposal fees, permits, and expected start/finish dates

A clear contract protects both sides. It should specify the exact products and colors, include a drawing or notes on flashing details, and define the payment schedule—often a modest deposit with progress payments tied to milestones, finishing with a holdback until final inspection. Ask about lien waivers from suppliers and subcontractors as payments are made. Distinguish between warranties: manufacturer coverage applies to materials (sometimes prorated) and workmanship coverage comes from the installer, typically spanning several years. Clarify how change orders are handled; surprises happen during tear‑off, and a transparent process avoids sticker shock. Set aside a contingency—commonly 10–15%—for unforeseen deck or framing repairs.

Day‑of logistics benefit from simple ground rules: where to stage materials, which power outlets are available, and how to secure the site at the end of each day. Keep communication open with a single point of contact who can answer questions about weather delays, inspection timing, or minor plan adjustments. After completion, walk the property together to confirm cleanup and review the final checklist. Conclusion: A thoughtful selection process, a detailed scope, and steady communication turn roof replacement from a stressor into a straightforward home upgrade. With materials matched to your climate and a crew that installs to code, you’ll gain a weather‑tight shell, quieter seasons, and one less major system to worry about for years to come.